Australia’s F135 Engine Depot Achieves Initial Depot Capability (IDC)

TAE Aerospace announced today it has successfully achieved all Initial Depot Capability (IDC) requirements for the repair and overhaul of the Pratt & Whitney F135 engine, which powers all three variants of the 5th Generation F-35 Lightning II fighter aircraft. With this achievement, TAE Aerospace’s F135 Maintenance, Repair, Overhaul &...

TAE Aerospace Acquires Arizona’s Southwest Airmotive

TAE Aerospace is delighted to announce it recently completed the purchase of Southwest Airmotive Corporation (SWA) of Eloy, Arizona in a move that will expand TAE Aerospace’s PT6 MRO capability in the United States.

Defense Propulsion MRO Centre of Excellence Wins National Award

Together with our Defense partner, Joint Strike Fighter Branch, TAE Aerospace's Defense Propulsion MRO Centre of Excellence has won a national award.

Aerospace MRO expands support in Land domain

Sharing MRO expertise and facilities between Air and Land platforms provides economic and operational benefits to Defence. TAE’s CEO, Andrew Sanderson, explains how.

GE partnership recognised by U.S. Ambassador visit and Australian award

The last week of November was one of celebration for us and our OEM partners, General Electric (GE).

TAE Aerospace to Support US Navy’s F/A 18 Super Hornets

In an arrangement believed to be the first of its kind outside the United States, Ipswich based TAE Aerospace, along with GE Aviation, will provide maintenance for selected engine parts for the US Navy’s F/A 18 Super Hornets and Growlers.

Celebrating 20 years in the aerospace industry

From very small beginnings in 2000 to now a global aerospace player, TAE Aerospace has come a long way over the past 20 years and will celebrate this significant anniversary as an Australian aerospace company throughout May 2020.

COVID-19 response – a message from our Chief Risk Officer

COVID-19 has had a significant impact on the world of business, and the world as we know it. This continues to unfold hour-to-hour. Our highest priority during these uncertain times is the health and well-being of our people, our customers and communities. Our Chief Risk Officer, John Hall, outlines our company’s COVID-19 response.

Insights into Australia’s position in the global aerospace supply chain

As guest speaker at the recent MRO Australasia conference, CEO Andrew Sanderson shared insights into the action needed to recover Australia’s competitive position in the global aerospace supply chain. He discussed our current position in the MRO market and his view on the actions required to recover our competitiveness globally.

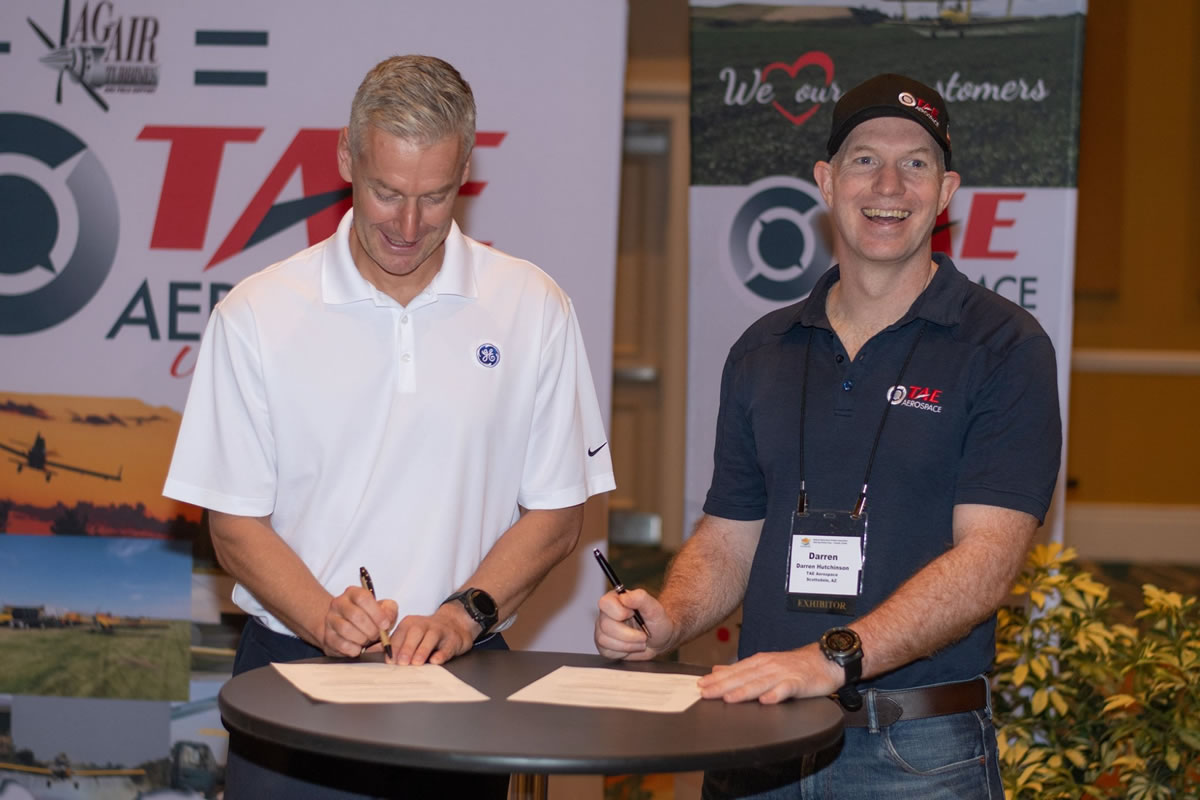

New GE approval for M601 and H80 Series engines

We’ve enjoyed working with GE and H-Series engine operators as an Asia-Pacific Designated Repair Center (DRC) since 2012. Following an agreement signed with GE late last year, we now hold the same approval for the United States, Canada, Central America and Latin America. The agreement was signed in Orlando, Florida.

Our first F135 engine module repair is now complete.

We were first assigned the Asia-Pacific Region’s F135 Maintenance, Repair, Overhaul and Upgrade (MRO&U) depot responsibility in 2015. Over the last five years, we’ve worked closely with Pratt & Whitney, the F-35 Joint Program Office in the U.S., and the Australian Government through the Joint Strike Fighter Division.

Thorough technical training can reduce your maintenance costs.

Whether you operate one agricultural aircraft or an entire fleet of TPE331-powered engines, thorough staff training can help lower your operating costs. Our goal is to equip customers with a skilled maintenance team. Well-trained staff members are capable of spotting and fixing problems early, reducing your maintenance costs.